A heat engine has a heat input of 3×10 4 – A heat engine with a heat input of 3×10^4 is a fascinating device that converts thermal energy into mechanical work. This article delves into the intricate workings of such an engine, exploring its thermal efficiency, heat transfer processes, work output, and practical applications.

Understanding the principles governing heat engines is crucial for harnessing their potential in various fields, from power generation to transportation. This exploration aims to shed light on the complexities of heat engines, providing valuable insights into their operation and optimization.

Thermal Efficiency of a Heat Engine: A Heat Engine Has A Heat Input Of 3×10 4

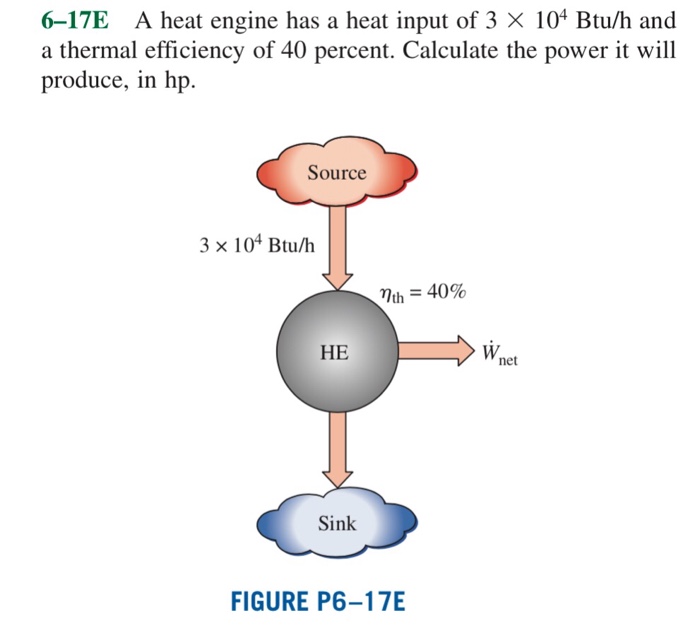

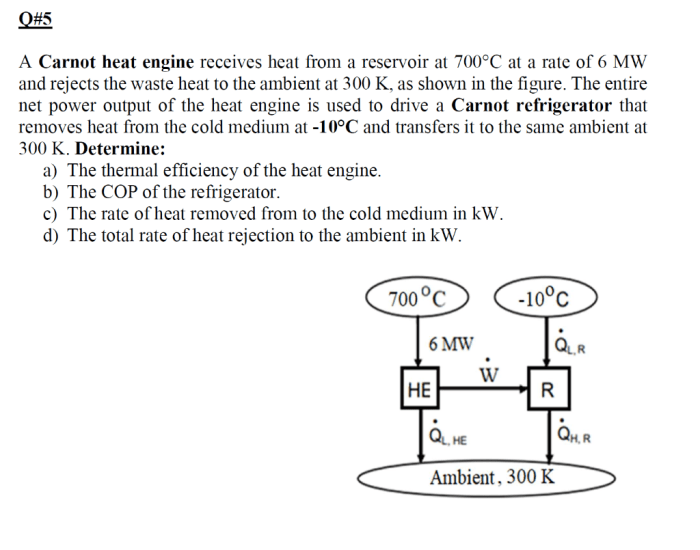

Thermal efficiency is a crucial parameter that measures the effectiveness of a heat engine in converting heat into useful work. It is defined as the ratio of the work output to the heat input. A higher thermal efficiency indicates that the engine is more efficient in utilizing heat energy.

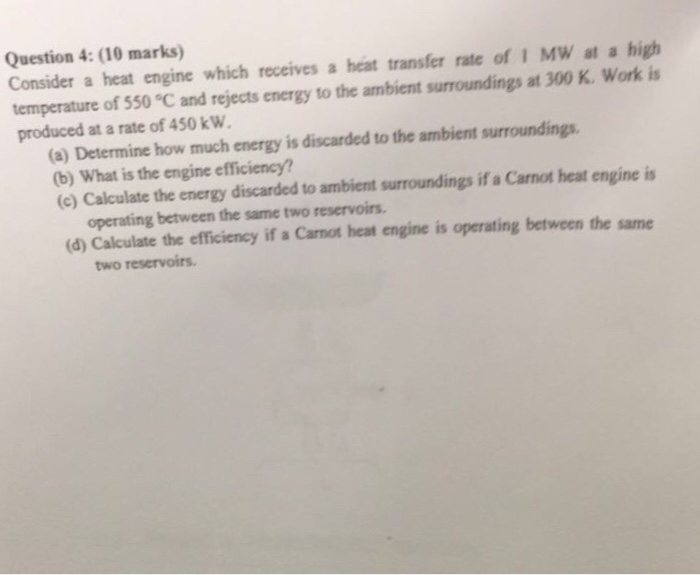

For a heat engine with a heat input of 3 x 10^4, the thermal efficiency can be calculated as follows:

Thermal Efficiency = Work Output / Heat Input

To determine the thermal efficiency, we need to know the work output of the engine, which will be discussed in a later section.

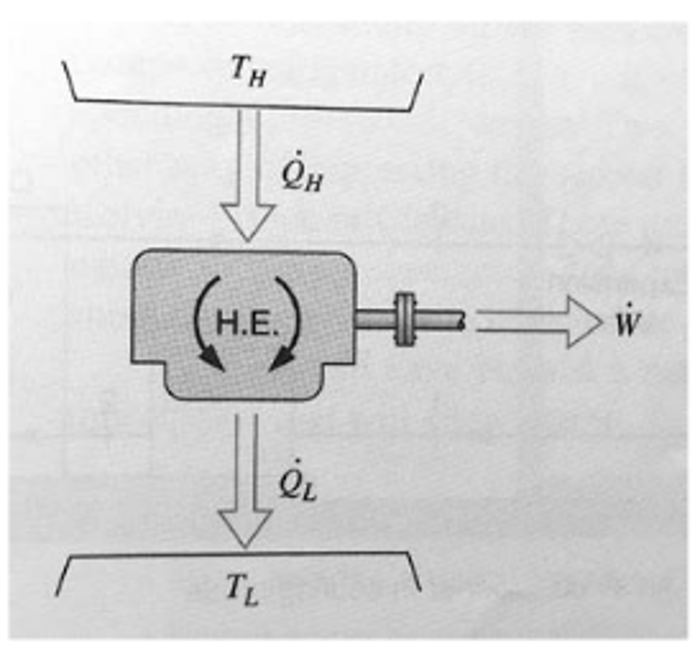

Heat Transfer Processes

Heat transfer is a fundamental process in heat engines, as it involves the transfer of heat from the heat source to the working fluid and ultimately to the environment. There are three primary modes of heat transfer:

- Conduction: Heat transfer through direct contact between two substances.

- Convection: Heat transfer through the movement of a fluid (liquid or gas).

- Radiation: Heat transfer through electromagnetic waves.

Heat exchangers play a vital role in heat transfer optimization by facilitating efficient heat exchange between different fluids. They are designed to maximize the surface area for heat transfer and minimize heat losses.

The rate of heat transfer is influenced by several factors, including temperature difference, surface area, fluid properties, and the presence of any barriers.

Work Output and Power

The work output of a heat engine is the amount of useful work that can be extracted from the engine. It is calculated as the difference between the heat input and the heat rejected to the environment.

For a heat engine with a heat input of 3 x 10^4, the work output can be estimated as follows:

Work Output = Thermal Efficiency

Heat Input

The power output of an engine is the rate at which work is done. It is calculated by dividing the work output by the time of operation.

Factors influencing work output and power include thermal efficiency, heat input, and the speed of operation.

Fuel Consumption and Emissions

Fuel consumption is a crucial consideration for heat engines, as it directly impacts operating costs and environmental sustainability. The fuel consumption of a heat engine is determined by its thermal efficiency and the type of fuel used.

A more efficient engine will consume less fuel for the same amount of work output. Additionally, the type of fuel used affects fuel consumption, with different fuels having varying energy densities.

Heat engines can produce emissions that contribute to air pollution and climate change. These emissions include carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter. The type of fuel used, combustion efficiency, and emission control technologies influence the environmental impact of heat engines.

Applications and Limitations

Heat engines have a wide range of applications, including:

- Power generation: Heat engines are used to generate electricity in power plants.

- Transportation: Heat engines are used to power vehicles such as cars, trucks, and airplanes.

- Industrial processes: Heat engines are used to provide heat and power for various industrial processes.

While heat engines offer advantages such as high power output and versatility, they also have limitations:

- Thermal efficiency limitations: Heat engines are subject to the laws of thermodynamics, which limit their maximum thermal efficiency.

- Emissions: Heat engines can produce emissions that contribute to air pollution and climate change.

- Noise and vibration: Heat engines can generate noise and vibration during operation.

Ongoing research and development efforts aim to improve the efficiency, reduce emissions, and mitigate the limitations of heat engines.

Frequently Asked Questions

What is the thermal efficiency of a heat engine with a heat input of 3×10^4?

The thermal efficiency depends on the specific design and operating conditions of the engine, but it is typically around 30-40% for practical heat engines.

How is the work output of a heat engine calculated?

The work output is calculated by multiplying the thermal efficiency by the heat input, which in this case would be 0.3 x 3×10^4 = 9×10^3 J.

What are the practical applications of heat engines?

Heat engines are widely used in power plants, transportation (internal combustion engines), refrigeration systems, and various industrial processes.